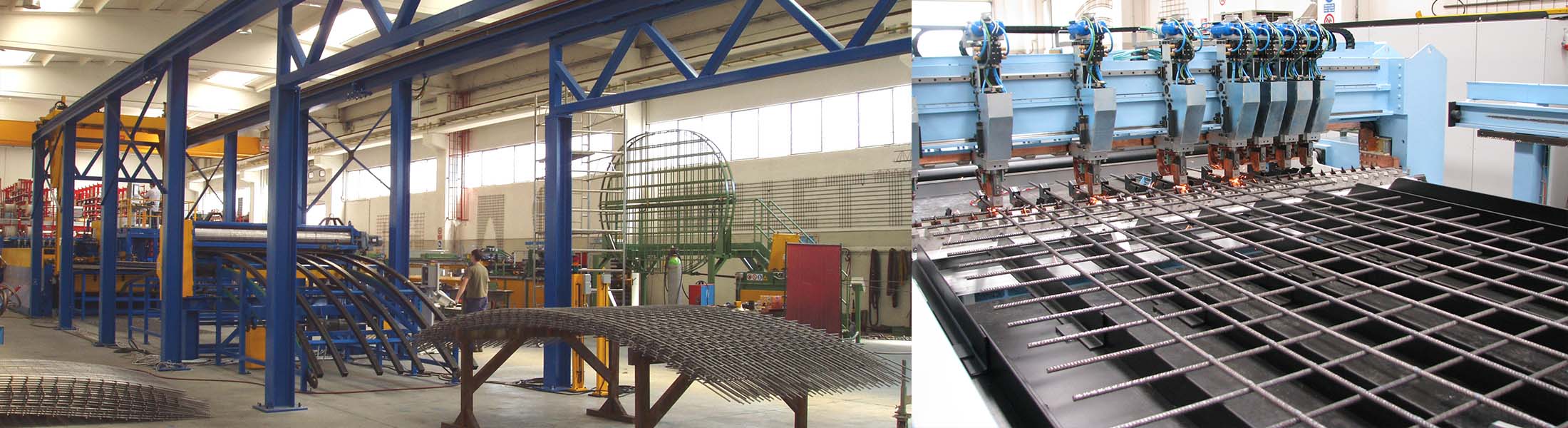

Plant for flat and curved mesh production for tunnel reinforcement

Flexiweld T

Automatic plant for the production of special engineered mesh, flat mesh or curved mesh for tunnel reinforcement.

The curved engineered mesh produced can be used as inner or outer reinforcement layers in tunnel cages.

Starting from wire in coils, electro-welded mesh is manufactured with programmable pitches and openings according to the design specifications, avoiding any scrap.

Mesh are processed fully automatically: welded, curved to the defined radius, handled and stacked.