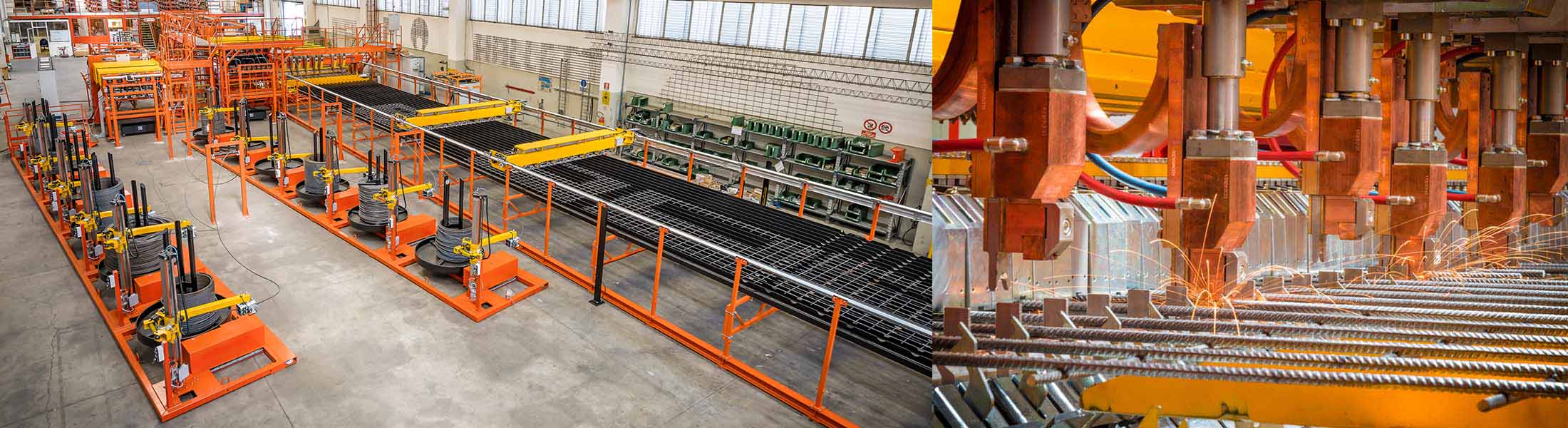

Special mesh welding plant

Flexiweld SF

Flexiweld SF is a flexible mesh welding plant from coil for the production of special mesh for precast concrete elements.

The SF model, thanks to its double straightening unit, is the high-speed version of the Flexiweld mesh welding machine series and is the right solution for precasters and mesh producers who need mesh for slabs or walls, mesh with holes and openings for doors and windows.

These mesh welding plants are characterized by a very high level of technology, low space requirements and affordability.

In addition, the number of welding heads can be adjusted to the desired performance.

If needed, the bespoke mesh welding machine can be combined with fully automatic mesh bending systems and logistical solutions.